KNOWING YOUR SAW CHAIN

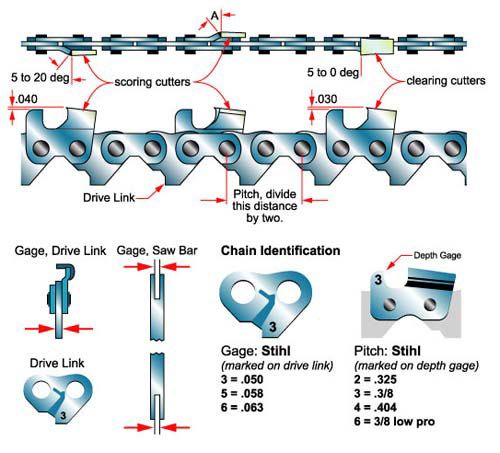

Multiple factors determine the best chain to use in given situations. Whilst different chains have different uses, every chain needs to be maintained and managed for optimal performance, this includes being sharpened and adjusted correctly. When your chain is cutting well it will produce large chips of wood. You will notice the difference. If we are going to talk chains then it helps to know the different features. In most cutting instances, semi-chisel chains will provide great all-around performance and require less sharpening than a full-chisel chain.

This article will bring you through the important features of a saw chain and provide you with the correct knowledge when choosing the right chain for your saw.

How does the type of wood make a difference?

For instance, when we are referring to hardwood, the most aggressive cutting option would be your full chisel cutter. This chisel will have the dimensions of a 90 degree angle and a square shape. However, due to the full chisel cutter having such an aggressive cut, the chisel won't last for long periods on hardwood or even dirty cutting conditions. Thus, more maintenance on the chain will be required throughout that type of cutting environment. Many users would favour a semi chisel chain over a full chisel cutter because it maintains a better stay sharp property and will remain sharper for longer periods.

Does bar length matter?

When using a longer bar (32" and longer) many people will often find a term called skip-tooth chain occurring. This method would be popular when you are cross cutting or milling. The chain will have the ability to clear the chip going through the saw, this is due to a less number of cutters. If the chain had the standard number of cutters rather than the reduced number, it would tend to get bogged down and drag because of the quantity of chips being pulled through. The benefits of reducing the number of cutter you use includes reducing the drag amount, thus, reducing the amount of power needed to get through that certain cut.

Side note: Chain speed is affected by the gauge thickness, pitch weight, gauge chain, bar length and chain length. You will require more power to pull a longer, thicker and heavier gauge through the wood, therefore reducing chain speed.

Saw powered by battery or gas, Is there a difference?

The biggest difference between a battery powered or a gas powered saw is the cc equivalence. For example a brand new battery powered chain saw may be equivalent to a 35-cc gas powered chain saw. It all depends on the level of power that particular chainsaw has, and you want to make sure that you are using a lower profile chain or lighter weight to ensure optimal power efficiency. In most cases, battery powered saws are going to be further down the cc spectrum.

Are Saw Chains made from different metals?

When it comes to saw chain metals, there are not many components. The complexity is the speed in which is required to produce and the linkages needed to form those chains. All the different parts of the chain such as the drive link, cutter, rivet etc will all have varied specifications, thus requiring multiple modifications to create. The process includes various heat methods, coating and plating operations. The process to produce a saw chain is quite complex and that is why there is only small number of manufacturers in the world that actually create them.

Note: Every chain manufacturer has there own coding specifications and metal treatments.