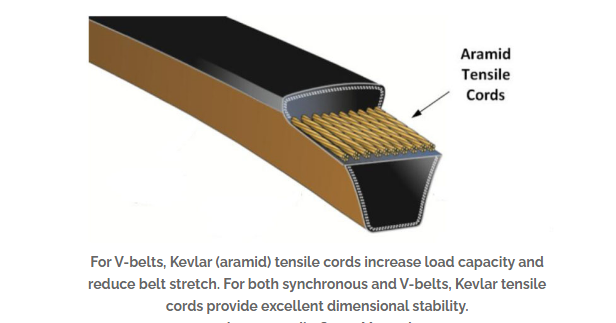

QUALITY IN BELTS, ARAMID/KEVLAR V NYLON BLACK

Aramid/ Kevlar v belts maintain a much higher tensile strength against your standard v belts (which use polyester cords). This increases the durability of the belt. One benefit of the kevlar belts is the stretch minimisation. Especially when enduring greater shock loads over a longer period of time. Aramid/Kevlar belts have a special dry cover for clutching applications and thus can withstand any twisting and bending.

Key benefits of Aramid/Kevlar belts include:

- Excellent performance for drives having clutching applications and backside idler drives

- There is a reduction with slippage while clutching

- These belts can withstand high levels of reverse flexing & twisting

- Due to the high tensile strength this belt provides a higher resistance to larger shock loads.

- Kevlar belts are key for the lawn mower and snow blower applications.

- They have a superior resistance to heat, oil, cracking, weather and ozone sunlight eat.

When comparing to Nylon Black Belts

In pure, undiluted form, Kevlar is lighter than Nylon and has greater tensile strength than Nylon. Believe it or not, pure Kevlar fabric actually is much less abrasion resistant than Cordura Nylon. Therefore Compared on a strength-to-weight ratio, Kevlar is about twice as strong as ordinary nylon fiber.

Even though Kevlar is suitable for a wide range of temperatures, it has a negative thermal coefficient of expansion, meaning that it shrinks as the temperature rises and lengthens as it cools. Since this behavior is the opposite of most other machine components (especially those made of metal) — which expand as temperature increases and contract as temperature decreases — Kevlar-reinforced belts may not be suitable in environments with significant temperature fluctuations.